Is Your Conservatory Too Cold In Winter & Too Hot In Summer?

Transform your conservatory with insulated roof panels and keep your conservatory the perfect temperature the whole year round. Transform that unusable space into a beautiful new room in less than a day and lower your energy bills.

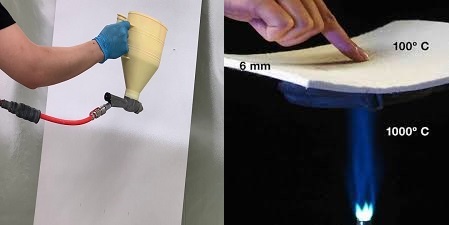

Our conservatory roof panels are made from a unique patented design that incorporates ultra-efficient roof insulation PIR boards, Kingspan K107. The efficiency of this material is 0.019 W/mK at a thickness of 25mm. Watts per meter Kelvin which is the unit of measurement for a material’s thermal conductivity. It indicates how efficiently a material transfers heat, with a lower number meaning better insulation and less heat or cold transfer. The Kingspan K107 is the best performing insulated panel available today.

This panel is then sprayed with Aerogel, a substance that carries the greatest insulation specifications of any insulator and is used in situations of tremendous heat or cold applications. This brings the thermal conductivity of the panel down to a measurement of 0.015 W/mK.

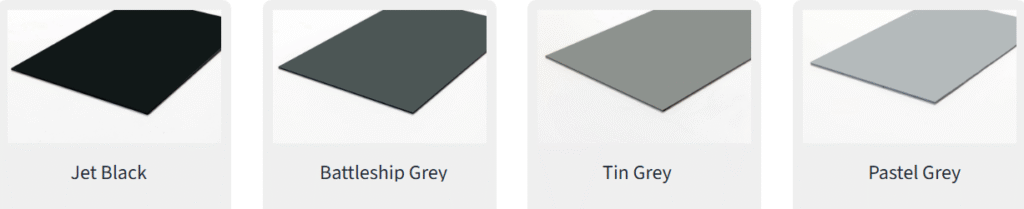

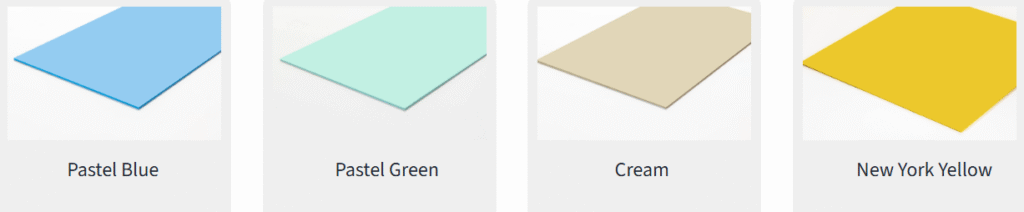

The panel is then covered both sides with a high impact and moisture resistance and highly reflective (Keeping the sun off), Upvc skin which is available in many colours. So, you could have white on the inside and a colour on the outside. This material offers outstanding thermal efficiency and outstanding noise reduction. The combination of all three materials offers, by far the most efficient thermal insulation available for a conservatory roof giving a U-Value of 0.53 W/m2K.

WARNING! Conservatory Roofs are not Load Bearing

When choosing to improve your conservatory roof it is very important to consider structural integrity. A conservatory is designed from the roof down. This means that the original supplier of the conservatory would have sent their measurements and specifications of the window and door system that make up the conservatory together with the brickwork or base-work and footings being used. The customer would have chosen whether to have a polycarbonate roof or a glass roof. All this information is sent to the roof manufacturer so they can design a roof that is fit for purpose.

Due to the modern fad of dropping heavy tiled roofs with plastered interiors onto the existing windows and doors of the conservatory has created a major issue. If you change from a conservatory roof to a tiled roof you must have Building Control approval as it is no longer considered a conservatory but is an extension. Building Control will need to check and approve that the existing conservatory structure can bear the load of the new roof. They will need to issue a Building Control certificate.

A building control certificate of completion is an official document from a local authority that confirms a construction project has been completed in compliance with building regulations and standards. It serves as proof that the work is safe and is a crucial document for potential buyers and when securing additional funds or mortgages for the property. The certificate is issued after the building control inspector conducts final checks and is satisfied that the project meets all necessary requirements. If you do not have the original specifications of the windows and doors then you cannot prove to Building Control that the structure is safe.

Just like the spray foam insulation scandal, if you change your conservatory roof to a solid tiled roof without a Building Control Certificate of Completion, you may not be able to sell your house.

Some suppliers are building conservatory replacement roofs out of timber. Using wooden trusses fixed to wooden ring beams screwed to the Upvc window and door frames. They then use wooden battens across the roof and attach plastic roof tiles. On the inside they again use wooden battens and plaster board and plaster ceilings. This is much heavier than the original window and door frames were designed to bear. Conservatory frames are only designed to take the weight of an aluminium roof with glass or polycarbonate sheets. To use a timer constructed roofs of this nature there must be brick support and RSJ supports keeping the load off the windows and doors as you would in a house wall.

Another option is to replace the conservatory glass or polycarbonate with Upvc panels and leave the original conservatory roof trusses in place. This work does not require Building Control approval as it is not viewed as a solid roof, although it may look solid.

Upvc flat panel have two 4mm outer skins and are filled with polystyrene to make up the thickness of the glass or polycarbonate they are replacing, 20mm – 28mm. The polystyrene is white in colour. There is another name for this type of insulation material called Styrofoam and it is blue. They are both polystyrene as Styrofoam is a brand name.

Polystyrene is a fair insulator with a U-Value between 0.8 -1.1 W/m2K. They are used in the flat panels you see in the bottom of a Upvc door. They have been used in conservatory roofs in the past, but they do not offer enough insulation for a roof. If replacing a five chambered polycarbonate roof sheet or a double-glazed glass panel, which is filled with argon gas, as in modern windows and doors, replacing those with a panel made from polystyrene or Styrofoam could make the roof less insulated.

To overcome this issue some companies are offering a system that uses a thicker polystyrene infill. Unfortunately, they wrap the polystyrene in an aluminium box. Aluminium is a poor insulator and is a conductive material. Any heat or cold from outside or inside will be transmitted across and around the surface to the opposite side. Known as thermal bridging. That is why in modern double-glazed glass units they do not use silver aluminium spacer bars between the two panes of glass as it allows heat and cold to cross. Nowadays, double-glazed glass units use plastic spacer bars, sometimes called composite, as plastic is an excellent insulation material as it is non-conductive.

Also, the thick part of the panel stops short of the conservatory roof trusses or glazing bars by as much as 30mm on either side and as much as 80mm on the edges, returning to a polystyrene thickness of the original roof thickness so it can fit into the glazing bars. The roof glazing bars are not insulated so about 100mm is very poorly insulated at the glazing bars and 80mm badly insulated at the roof edge. These companies quote the insulation figures of the thickest part of the panels which is 75mm and do not mention the overall insulation. As heat goes to cold, your valuable heat will escape around the very poorly insulated sides of these panels.

The cheapest way to insulate a conservatory roof is also the most dangerous. As mentioned before, conservatory roofs are not load bearing. They use the weight of the polycarbonate sheets or glass units to push down and clip into the glazing bars of the conservatory. This push down effect seals glazing bars against the roof material preventing rainwater getting in.

Some suppliers are advocating screwing wooden battens to the underside of the glazing bars and then stapling multi-layer insulation to the underside of the conservatory. Multi-Layer insulation is an excellent insulator. It is also very heavy. You must not screw anything into the conservatory roof glazing bars as they are sealed boxes and designed to channel any rainwater away from the roof. Screwing into them will cause a leak. These companies then add a second wooden batten to the underside of the first wooden batten and then screw on pvc cladding. This total weight will pull down on the conservatory glazing bars and open up the rubber seals that push against the glass or polycarbonate roof sheets allowing rainwater to enter.